Production Systems

Institute of Production Science (wbk) - Machines, Equipment and Process Automation

Most of the cost of lithium-ion cells and batteries is attributable to

their production. The objective is the development and

prototypical representation of economical production processes.

Process Development and Optimization:

- Development of novel stacking processes

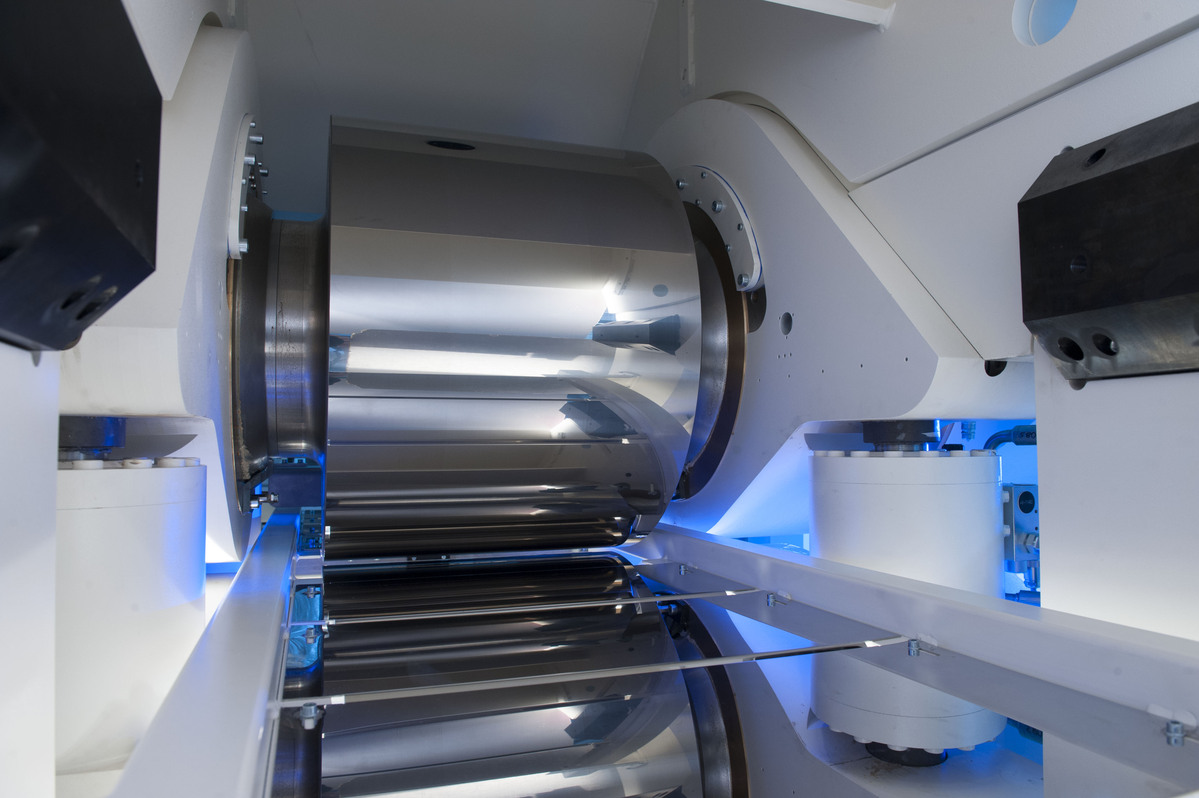

- Optimization of the calendaring process

- Development of format-flexible production processes

- Development of a system for the disassembly of battery modules

- Development of handling solutions for the manufacture of battery modules

Process Studies:

- Investigation of the behavior of pouch cell foils in deep drawing

- Calendaring tests

- Studies of the mechanical behavior of electrodes.

Development of Production Systems:

- Development of robot-supported agile production technologies for format-flexible battery manufacture

- Establishment of quality assurance systems

Contact: Sebastian Schabel