Zellentwicklung/-tests

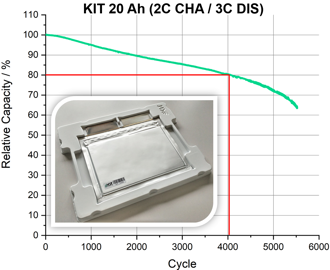

Im Bereich der Zellentwicklung liegt der Schwerpunkt vor allem in der produktnahen Forschung und Entwicklung der Lithiumionenzelltechnologie mit dem Ziel, hochwertige und leistungsfähige Zellen zu entwickeln. Dabei steht die Reduzierung der Zellkosten bei gleichzeitiger Steigerung von Energiedichte, Zyklenfestigkeit, kalendarischer Lebensdauer und intrinsischer Sicherheit im Fokus. Die Produktionslinie bietet dafür die Möglichkeit, Lithiumionenpouchzellen im Laborformat und Großformat (bis zu 20 Ah) zu fertigen. Dies findet in einem Trockenraum bei einem Taupunkt von bis zu -80°C statt, was unter anderem einer der Faktoren für die hohe Qualität und somit auch die Lebensdauer der selbstproduzierten Zellen ist. Es ist sowohl der Bau von Prototypen, als auch Kleinserien möglich.

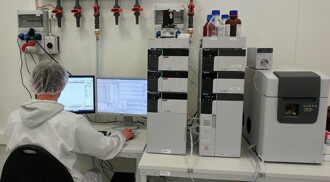

In der Zellentwicklung spielt auch die Qualitätskontrolle und Fehlerforschung eine wichtige Rolle. Zur Klärung von Ursache und Wirkungsbeziehungen finden Zellbautests mit forciert herbeigeführten Fehlern statt. Für die Zellcharakterisierung und die Durchführung von Post-mortem Analysen stehen Methoden wie Elektronenmikroskopie oder Röntgenanalysen zur Verfügung. Darüber hinaus steht die Entwicklung neuer Analysemethoden im Vordergrund, mit der neue Elektrolytrezepturen und Formierprozesse ergänzend zu Zyklisierungsexperimenten untersucht werden können.

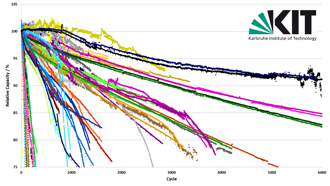

Im Bereich der Zelltests können zur Messung der Zellperformance elektrische Zellcharakterisierungen und anwendungsspezifische Evaluierungen durchgeführt werden. Dies beinhaltet Dauerzyklentests für großformatige Zellen (Kanalstromstärken bis 200 A) und kleinformatige Laborzellen (Kanalstromstärken bis 3 A). Darüber hinaus können kalendarische Lebensdaueruntersuchungen bei verschiedensten Temperaturen durchgeführt werden. Für spezielle sicherheitskritische Testbedingungen wie z.B. beschleunigtes Zyklisieren bei niedrigen Temperaturen stehen darüber hinaus Einzeleinhausungen mit Direktklimatisierung und Stromstärken bis 360 A zur Verfügung.

Weitere Informationen, siehe Batterietechnikum.